Industry 4.0. The Cefla Finishing solutions

Virtual Reality by Cefla Finishing at InPrint Munich 2017.

At Cefla Finishing, the professionalisms needed to fully exploit the technological opportunities of Industry 4.0. Described as the 4th Industrial Revolution, the current trend towards industrial automation, known as ‘Industry 4.0’, is much more than just another development.

There is a radical change in the approach to production, which becomes computerised and “connected” to optimise productivity and generate efficiency. It is more and more essential for us to monitor, control, interact and generate efficiency in our business.

«Thanks to the enabling factors of Industry 4.0 – says Alberto Maestri, Managing Director Business Unit Finishing in Cefla – we are able to connect the digital world to the real world, and the world of machines to the world of people. We are doing this, today, to deliver tangible value to our projects and our customers’ and partners’ businesses.»

By 2020 there will be more than a billion connected devices, meaning an immense body of data, available immediately, which will open the way to vast analysis capabilities. Here at Cefla Finishing, we are skilled in achieving the right combination between the efficiency of mass production and the personalisation required to meet our customers’ specific needs.

Three main lines

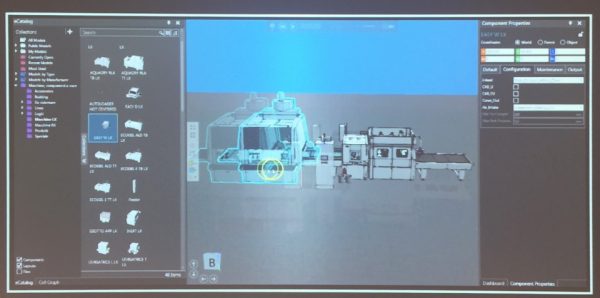

Cefla’s Industry 4.0 project is structured along 3 main lines:

1. Design and simulation 2. Supervision and control 3. Efficientization and efficiency.

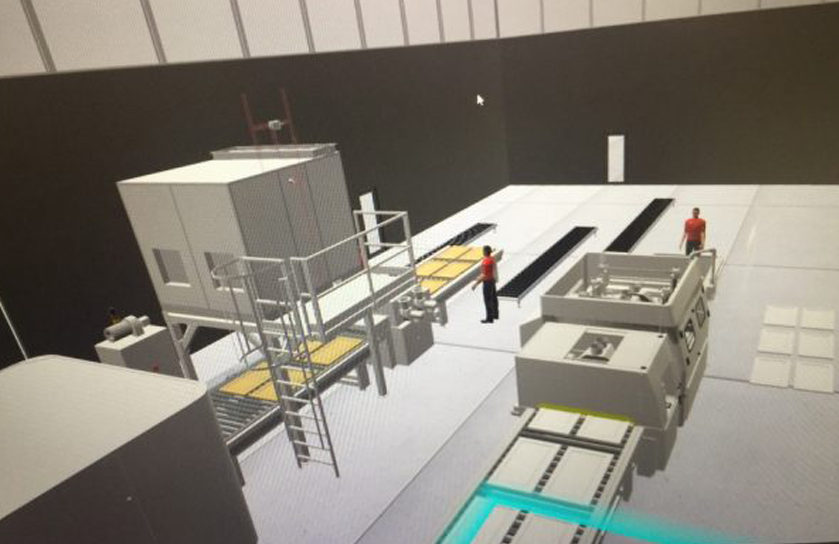

With virtual reality you feel you have full control of everything and can move freely through space, with no blind spots. To try it is to feel the tangible value of an innovative spirit: To truly appreciate the potentials of your business and the way we design it. To try it is a unique experience. To enter your own, simulated, three-dimensional world, open for exploration down to the last centimetre, in every direction.

«We are talking about our virtual reality project, through which we express our innovative technology and product choices, make them tangible and generate real value for our customers.»

Cefla’s technicians have created a unique experience: thanks to a VR visor – with no restrictions or blind spots – you are fully immersed in the production line we are designing, getting right up to the individual machines and every detail of their operation. It is easy to enter this immersive dimension: the key is a VR visor which covers every possible eye and head movement, combined with a computer and a controller, for interacting with the machines and technologies re-created in this space.

«Here at Cefla Finishing, we know that being innovative means working closely with customers and being ready with solutions to their specific needs. The challenge we face today is to exploit digital technology’s potentials to design efficiency and create the tangible, personalised, measurable value that makes us the best partner for our customers. Today we are also tackling this challenge through our Virtual Reality project.»

This experience will be ready and waiting for you at InPrint! See you soon at the Cefla stand: Hall A6, Stand 634.

For more information about visit: https://www.ceflafinishing.com/en/landings/smartfactory https://www.ceflafinishing.com/de/landings/smartfactory