Levi Strauss wins with Tonello’s NoStone

To Levi Strauss & Co. and Tonello the first ITMA Sustainable Innovation Award winner, for the innovative sustainable NoStone garment washing technology.

Levi Strauss & Co. of USA, known worldwide for its authentic vintage look jeans, is the winner of the first ITMA Sustainable Innovation Award, It clinched the ITMA Industry Excellence Award category from two other finalists: Berto Industria Tessile (Italy) and Gebrüder Otto (Germany).

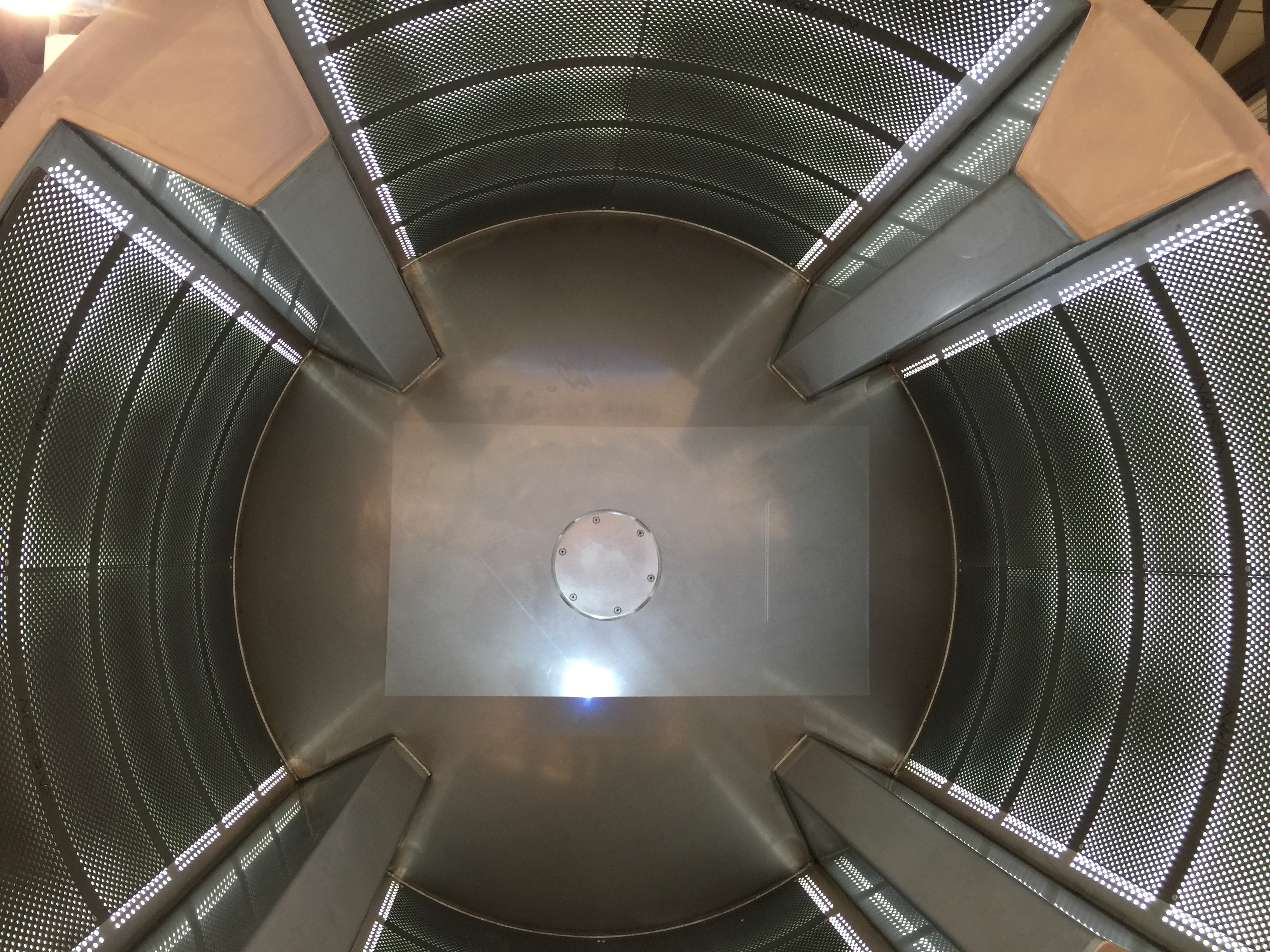

Using the NoStone® garment washing technology from Tonello, an ITMA 2015 exhibitor, Levi Strauss & Co. has started preliminary development work in their Plock facility in Poland. Tonello’s technology provides Levi Strauss an important first step to solving an industry challenge in denim finishing – the use of pumice stones which have environmental, economic and mechanical disadvantages.

CEMATEX, the European Committee of Textile Machinery Manufacturers, launched the ITMA Sustainable Innovation Award as part of its ongoing efforts to encourage and recognise outstanding industry members and post-graduate students for their contributions to the sustainable development of the global textile and garment industry. The two award categories are ITMA Industry Excellence Award for ITMA 2015 exhibitors and their clients, and the R&I Excellence Award for post-graduate students of institutions participating in the Research & Innovation Pavilion.

Technological innovations

The Industry Excellence Award recognises textile and garment manufacturers who have leveraged on technological innovations to advance business sustainability that benefit people, planet and profit. The finalists have worked closely with ITMA 2015 exhibitors to introduce innovative solutions to their production process or products. Finalist Berto Industria Tessile is a leading vertically integrated manufacturer of denim products. It leverages on the Matex Eco Applicator range by ITMA exhibitor Monforts to significantly reduce the amount of liquid needed in finishing denim fabrics, leading to energy savings and a huge reduction in waste water produced.

On the other hand, Gebrüder Otto is a leading yarn manufacturer which implemented spinitsystems® della Mayer & Cie’s to produce single jersey fabric using up to 35 per cent less energy compared to the conventional process. For the R&I Excellence Award – Masters category, Jan Vincent Jordan, Institut Für Textiltechnik of RWTH Aachen University is the winner. His Master’s Thesis: ‘Development & Assembly of a Test Bench for the Analysis of Magnetic Weft Insertion’ clinched top marks with the judges. The two other finalists were: Jenifer Schneidereit, Hochschule Niederrhein for her Master’s Thesis: ‘Sustainable Water Use in Textile Wet Processing: Development of a List of Improvement Measures for a Self-Assessment Tool for Factories’, and Moniruddoza Ashir, Institute of Textile Machinery and High Performance Material Technology, TU Dresden, for his Master’s Thesis: ‘Development of Hybrid Woven Structures for Lightweight Applications’.