Colour separation in textile printing

XerioSEP is a software specially developed to revolutionize the colour separation for multichrome textile printing up to 12 colours, both traditional and digital.

It could seem to be no more space for true innovative solutions, as it is colour separations for four-color printing (CMYK), but we discover a revolutionary software for multichromatic colour separation (up to 12 colours) specific for the textile industry. We therefore considered it appropriate to deepen this item to give the readers a new working tool that could open up new opportunities, in particular for textile designers.

We turn to Gianpaolo Coin, CEO, Grafco, an Italian company specialized in the production of inks for screen printing and digital textile machines, who has followed the development and implementation of this innovative tool.

MPA – Today for those involved in the prepress industry the colour separation is normally intended the four-colour (CMYK) a firmly established technique. Why did you decided to develop a new specific separation software?

Coin – It is true that the four-colour separation has been developed since the early 1900s for multi colour imaging, using the minimum number of inks, 4 in fact or, better, 3 plus black. But in screen printing (and digital too) for textile industry for the final customer it is not so important the correct “reproduction” of picture on fabric, maybe that was originally presented printed on paper, but also its colour ‘effect’.

MPA – As to say that unlike the printing of paper catalogs or magazines, which require matching the original colours, on fabric the images must have something more, let us say, a creative impact?

Coin – Designers and creatives are always looking to get, through screen printing and now also digital printing, a special “visual impact” of the image with an extended and powerful chromatic presence, that captures the attention and seduce the eye of the look. In a nutshell they seek a “good print” and a “deep print”.

MPA – So, it seems that the imaging for textiles printing, or even for T-shirts is a task for prepress hieratic gurus, if we are allowed the term …

Coin – In fact it is a question of simple physics. When using CMYK to obtain a wide gamut it is necessary to work in the best possible conditions of deposition of the colour inks and black: as is the case, for example, of the offset technology printed on white paper with low absorption and with all parameters of ink deposition under control.

MPA – But the fabric absorbs inks …

Coin – Indeed, but not only. When we print on fabric an amount of parameters are involved, such as the texture of the textile support, its fibre composition, the degree of ink absorption, the deposition differences during printing of various colors, which reduce the final response. To date, the companies that operate for high quality textile tend to work with 6, 8, 10 … N colours to achieve a result with a visual effect of impact.

MPA –Your new XerioSEP software can automatically generate a separation ready for printing for more than 4 colours?

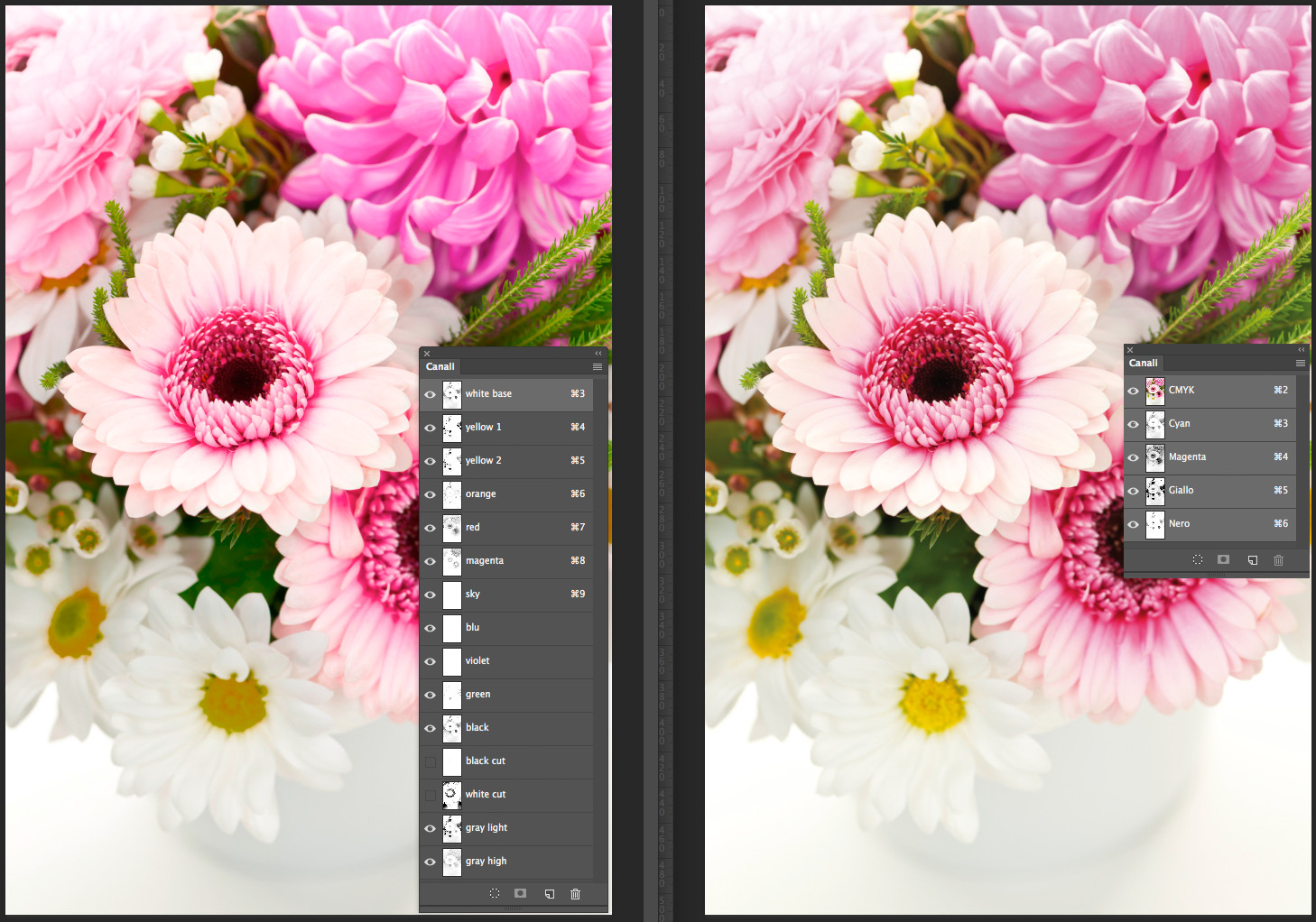

Coin – Our software generates, in an extremely simple way, a separation of up to 12 colours of the original image. The software works with powerful colour mapping algorithms so that the file, once separated from a chromatic point of view, in order to be as close as possible to the original image effect.

Competences and creativity

MPA – A special knowledge is required for this?

Coin – Our staff prepares prepress operators to correctly use XerioSEP, interpretation and proper use of such separations; then, when they acquired a good experience, we leave themselves full freedom to use XerioSEP to get the best possible result according to their sensitivity and creativity, and according to the images to be processed.

MPA – This separation in more colours of XerioSEP is usable for any kind of image?

Coin – Actually, each image has a colour palette and a different colour complexity; that’s why we consider it very important to teach, with a special workshop to the specialists interested in our system, to make best use of separations generated by XerioSEP. Who knows how to use XerioSEP considers this an invaluable tool to get in a few minutes separations for textile prints of high quality and eye impact.

Quality and cost saving

MPA – But, it may not be enough Photoshop or something similar ? There are various product on internet …

Coin – We know that on internet are advertised colour separation systems and plug-ins for Photoshop that promise miracles. But, as determined by our own customers who are using XerioSEP after years of experimentation and trials with this APPs downloaded from internet, the results obtained with our system is in no way comparable with those proposals.

MPA – Who decides how many colours in the production process should be separated to be allocated to the textile printing?

Coin – XerioSEP is used to adjust the separation of the number of colours to the kind of printing machines available for production. It is obvious that if a company owns carousel machines to 8 colors, they do not need a separation to 9 or 10 colors: 8 are enough.

Furthermore, the number of colours can also be decided in advance for a matter of cost and in this case XerioSEP can be used to reduce the number of colours to a minimum to obtain a qualitatively valid result. Often our customers have been proud to send us prints separated by XerioSEP with 8-color, that were more pleasing, but also easier and more economic to print compared to the same previously produced at 12 colour.

Also for digital printing

MPA – The multichrome colours separation is used only for screen printing?

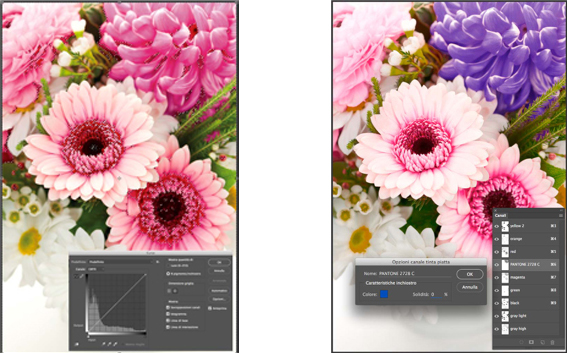

Coin – The power of the separation of XerioSEP in N spot colours is also very useful in the case of preparing images for digital textile printing. XerioSEP allows extremely quickly separate inside the image the areas with shades that we want to weaken or highlight from a point of view of colour compared to the other areas of the image. Furthermore, the particular colour mapping algorithm is extremely effective in creating “colourways” for conventional continuous textile printing, as we can see in the image below.

MPA – What is the next step to the colours separation of the image?

Coin – An image separated for example to 8 colours in Photoshop results as the overlap of 8 levels of colour, in practice we will see on the computer screen an overlay of 8 shades. Now, to reproduce the separate image we are obliged to print overlapping the 8 shades using the silk-screen technique.

MPA – Then a fully dedicated software?

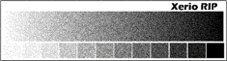

Coin – Sure. That’s why to get the best possible result, we have developed the first XerioRIP RIP entirely dedicated to screen printing and textile printing, which prints very precisely (without Moiré effect) and flawless gradients generated by XerioSEP.

MPA – Which is the visible difference between a separate four-colour printing and a multichrome printing?

Coin – First of all we should remember that our eye is a wonderful tool and is able to perceive an amount of information at a glance. In general, the four-colour printing appears “flat” and without depth compare to the multichrome printing. Moreover, the reproduction of CMYK colours is decidedly ‘less live’ for the reasons explained above. The largest real difference is evident by comparing prints taken at various stages of the process (for example if we compare some printed matters, the # 20, # 80, the # 200, and so on). In CMYK printing we will have a mix of prints with various dominant, sometimes tending to yellow, sometimes red or blue. But this simply is not the case when we use a separation made in multichrome spot color.

MPA – This particular approach to the image reproduction has also been used in traditional block, roller or cylinder printing?

Coin – Most of the tests and the following productions in print of continuous fabric, using the combined XerioSEP + XerioRIP were made in various Countries with very exciting results. Unfortunately, in Italy and other European Countries, as soon as the printers are faced with complex images to be printed with the technology of the traditional press, they turn the work in digital printing. It seems that no matter to anyone, that in this way there is uniformity in results from that which would produce any Indian, China or Bangladesh printer, as they often also have the same digital printing machine.

MPA – A rematch of screen printing?

Coin – I am personally convinced, from the results obtained, that the textile screen printing up to date with the latest technological solutions, is strategic to create products that “make a difference” and quite capable of producing large visible and perceptible to quality. Do not forget that digital printing does not reach 10% of textile printing, and in some countries only 2%.